Допуски подшипников

Допуски подшипников стандартизированы на отечественном и международном уровне в соответствии с системой стандартизации ISO. Подшипники изготавливаются с определенной точностью и, в общем, характеризуются классом точности P0. На заказ, могут изготавливаться подшипники, имеющие класс точности P6, P5, P4 и P2. Последние типы подшипников производятся для специальных назначений таких, как высокоточная направляющая оси или сверхвысокие скорости качения. Предоставляются таблицы допусков, касающиеся:

- размеров подшипников;

- размеров закругления кромок подшипниковых колец, монтажных фасок.

Условное обозначение допусков

Допуски радиальных подшипников нормального класса точности (за исключением конических роликоподшипников)

| d | Δd mp | Vdp | V dmp | ΔB s | VBS | K ia | |||||

| Ряд диаметров | |||||||||||

| сверх | до | max | min | 8,9 max | 0,1 max | 2,3,4 max | max | max | min | max | max |

| mm | µm | µm | µm | µm | µm | µm | µm | µm | µm | µm | µm |

| 2,5 | 10 | 0 | -8 | 10 | 8 | 6 | 6 | 0 | -120 | 15 | 10 |

| 10 | 18 | 0 | -8 | 10 | 8 | 6 | 6 | 0 | -120 | 20 | 10 |

| 18 | 30 | 0 | -10 | 13 | 10 | 8 | 8 | 0 | -120 | 20 | 13 |

| 30 | 50 | 0 | -12 | 15 | 12 | 9 | 9 | 0 | -120 | 20 | 15 |

| 50 | 80 | 0 | -15 | 19 | 19 | 11 | 11 | 0 | -150 | 25 | 20 |

| 80 | 120 | 0 | -20 | 25 | 25 | 15 | 15 | 0 | -200 | 25 | 25 |

| 120 | 180 | 0 | -25 | 31 | 31 | 19 | 19 | 0 | -250 | 30 | 30 |

| 180 | 250 | 0 | -30 | 38 | 38 | 23 | 23 | 0 | -300 | 30 | 40 |

| 250 | 315 | 0 | -35 | 44 | 44 | 26 | 26 | 0 | -350 | 35 | 50 |

| 315 | 400 | 0 | -40 | 50 | 50 | 30 | 30 | 0 | -400 | 40 | 60 |

| 400 | 500 | 0 | -45 | 56 | 56 | 34 | 34 | 0 | -450 | 50 | 65 |

| 500 | 630 | 0 | -50 | 63 | 63 | 38 | 38 | 0 | -500 | 60 | 70 |

| 630 | 800 | 0 | -75 | - | - | - | - | 0 | -750 | 70 | 80 |

| 800 | 1000 | 0 | -100 | - | - | - | - | 0 | -1000 | 80 | 90 |

| 1000 | 1250 | 0 | -125 | - | - | - | - | 0 | -1250 | 100 | 100 |

| 1250 | 1600 | 0 | -160 | - | - | - | - | 0 | -1600 | 120 | 120 |

| 1600 | 2000 | 0 | -200 | - | - | - | - | 0 | -2000 | 140 | 140 |

| D | ΔD mp | VDp | Подшипники с герметизированными опорами |

V Dmp | K ea | ||||

| сверх mm |

до mm |

max µm |

min µm |

Ряд диаметров |

max µm |

max µm |

|||

| 8,9 max µm |

0,1 max µm |

2,3,4 max µm |

max µm |

||||||

| 6 | 18 | 0 | -8 | 10 | 8 | 6 | 10 | 6 | 15 |

| 18 | 30 | 0 | -9 | 12 | 9 | 7 | 12 | 7 | 15 |

| 30 | 50 | 0 | -11 | 14 | 11 | 8 | 16 | 8 | 20 |

| 50 | 80 | 0 | -13 | 16 | 13 | 10 | 20 | 10 | 25 |

| 80 | 120 | 0 | -15 | 19 | 19 | 11 | 26 | 11 | 35 |

| 120 | 150 | 0 | -18 | 23 | 23 | 14 | 30 | 14 | 40 |

| 150 | 180 | 0 | -25 | 31 | 31 | 19 | 38 | 19 | 45 |

| 180 | 250 | 0 | -30 | 38 | 38 | 23 | - | 23 | 50 |

| 250 | 315 | 0 | -35 | 44 | 44 | 26 | - | 26 | 60 |

| 315 | 400 | 0 | -40 | 50 | 50 | 30 | - | 30 | 70 |

| 400 | 500 | 0 | -45 | 56 | 56 | 34 | - | 34 | 80 |

| 500 | 630 | 0 | -50 | 63 | 63 | 38 | - | 38 | 100 |

| 630 | 800 | 0 | -75 | 94 | 94 | 55 | - | 55 | 120 |

| 800 | 1000 | 0 | -100 | 125 | 125 | 75 | - | 75 | 140 |

| 1000 | 1250 | 0 | -125 | - | - | - | - | - | 160 |

| 1250 | 1600 | 0 | -160 | - | - | - | - | - | 190 |

| 1600 | 2000 | 0 | -200 | - | - | - | - | - | 220 |

| 2000 | 2500 | 0 | -250 | - | - | - | - | - | 250 |

Допуски конических роликоподшипников нормального класса точности

| d | Δdmp | Vdp | Vdmp | ΔBs | -ΔCs | Kia | ΔTs | ΔT1s | ΔT2s | |||||

| сверх | до | max | min | max | max | max | min | max | max | min | max | min | max | max |

| mm | mm | µm | µm | µm | µm | µm | µm | µm | µm | µm | µm | µm | µm | µm |

| 10 | 18 | 0 | -12 | 12 | 9 | 0 | -120 | 15 | 200 | 0 | 100 | 0 | 100 | 0 |

| 18 | 30 | 0 | -12 | 12 | 9 | 0 | -120 | 18 | 200 | 0 | 100 | 0 | 100 | 0 |

| 30 | 50 | 0 | -12 | 12 | 9 | 0 | -120 | 20 | 200 | 0 | 100 | 0 | 100 | 0 |

| 50 | 80 | 0 | -15 | 15 | 11 | 0 | -150 | 25 | 200 | 0 | 100 | 0 | 100 | 0 |

| 80 | 120 | 0 | -20 | 20 | 15 | 0 | -200 | 30 | 200 | -200 | 100 | -100 | 100 | -100 |

| 120 | 180 | 0 | -25 | 25 | 19 | 0 | -250 | 35 | 350 | -250 | 150 | -150 | 200 | -100 |

| 180 | 250 | 0 | -30 | 30 | 23 | 0 | -300 | 50 | 350 | -250 | 150 | -150 | 200 | -100 |

| 250 | 315 | 0 | -35 | 35 | 26 | 0 | -350 | 60 | 350 | -250 | 150 | -150 | 200 | -100 |

| 315 | 400 | 0 | -40 | 40 | 30 | 0 | -400 | 70 | 400 | -400 | 200 | -200 | 200 | -200 |

| 400 | 500 | 0 | -45 | 45 | 34 | 0 | -450 | 70 | 400 | -400 | - | - | - | - |

| 500 | 630 | 0 | -50 | 50 | 38 | 0 | -500 | 85 | 500 | -500 | - | - | - | - |

| 630 | 800 | 0 | -75 | 75 | 56 | 0 | -750 | 100 | 600 | -600 | - | - | - | - |

| 800 | 1000 | 0 | -100 | 100 | 75 | 0 | -1000 | 120 | 750 | -750 | - | - | - | - |

| 1000 | 1250 | 0 | -125 | - | - | 0 | -1250 | 120 | 1000 | -1000 | - | - | - | - |

| D | ΔDmp | VDp | VDmp | Kea | ||

| сверх | до | max | min | max | max | max |

| mm | mm | µm | µm | µm | µm | µm |

| 18 | 30 | 0 | -12 | 12 | 9 | 18 |

| 30 | 50 | 0 | -14 | 14 | 11 | 20 |

| 50 | 80 | 0 | -16 | 16 | 12 | 25 |

| 80 | 120 | 0 | -18 | 18 | 14 | 35 |

| 120 | 150 | 0 | -20 | 20 | 15 | 40 |

| 150 | 180 | 0 | -25 | 25 | 19 | 45 |

| 180 | 250 | 0 | -30 | 30 | 23 | 50 |

| 250 | 315 | 0 | -35 | 35 | 26 | 60 |

| 315 | 400 | 0 | -40 | 40 | 30 | 70 |

| 400 | 500 | 0 | -45 | 45 | 34 | 80 |

| 500 | 630 | 0 | -50 | 50 | 38 | 100 |

| 630 | 800 | 0 | -75 | 75 | 55 | 120 |

| 800 | 1000 | 0 | -100 | 100 | 75 | 120 |

| 1000 | 1250 | 0 | -125 | 125 | 94 | 120 |

| 1250 | 1600 | 0 | -160 | 160 | 120 | 120 |

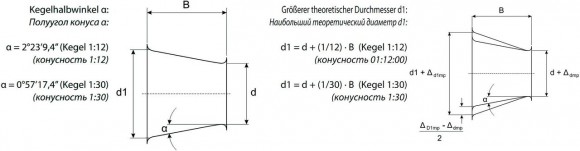

Конические отверстия

Допуски для конических отверстий

| d | Нормальный класс допуска, P6 | Нормальный класс допуска, P5 | |||||||||

| Δdmp | Vdp1 | Δd1mp | -Δdmp | Δdmp | Vdp1 | Δd1mp | -Δdmp | ||||

| сверх | до | max | min | max | 0,1 max | 2, 3, 4 max | max | min | min | max | max |

| mm | mm | µm | µm | µm | µm | µm | µm | µm | µm | µm | µm |

| 18 | 30 | 21 | 0 | 13 | 21 | 0 | 13 | 0 | 13 | 13 | 0 |

| 30 | 50 | 25 | 0 | 15 | 25 | 0 | 16 | 0 | 15 | 16 | 0 |

| 50 | 80 | 30 | 0 | 19 | 30 | 0 | 19 | 0 | 19 | 19 | 0 |

| 80 | 120 | 35 | 0 | 25 | 35 | 0 | 22 | 0 | 22 | 22 | 0 |

| 120 | 180 | 40 | 0 | 31 | 40 | 0 | 25 | 0 | 25 | 25 | 0 |

| 180 | 250 | 46 | 0 | 38 | 46 | 0 | 29 | 0 | 29 | 29 | 0 |

| 250 | 315 | 52 | 0 | 44 | 52 | 0 | 32 | 0 | 32 | 32 | 0 |

| 315 | 400 | 57 | 0 | 50 | 57 | 0 | 36 | 0 | 36 | 36 | 0 |

| 400 | 500 | 63 | 0 | 56 | 63 | 0 | 40 | 0 | - | 40 | 0 |

| 500 | 630 | 70 | 0 | - | 70 | 0 | 44 | 0 | - | 44 | 0 |

| 630 | 800 | 80 | 0 | - | 80 | 0 | 50 | 0 | - | 50 | 0 |

| 800 | 1000 | 90 | 0 | - | 90 | 0 | 56 | 0 | - | 56 | 0 |

| Нормальный класс допуска | ||||||

| d | Δdmp | V dp1 | Δd1mp | -Δdmp | ||

| сверх | до | max | min | max | 0,1 max | 2,3,4 max |

| mm | mm | pm | pm | pm | pm | pm |

| 80 | 120 | 20 | 0 | 25 | 40 | 0 |

| 120 | 180 | 25 | 0 | 31 | 50 | 0 |

| 180 | 250 | 30 | 0 | 38 | 55 | 0 |

| 250 | 315 | 35 | 0 | 44 | 60 | 0 |

| 315 | 400 | 40 | 0 | 50 | 65 | 0 |

| 400 | 500 | 45 | 0 | 56 | 75 | 0 |

| 500 | 630 | 50 | 0 | 63 | 85 | 0 |

| 630 | 800 | 75 | 0 | - | 100 | 0 |

| 800 | 1000 | 100 | 0 | - | 100 | 0 |

Допуск упорных подшипников

| Нормальный класс допуска P6, P5 | |||||||

| d | Δdmp | Vdp | Si1 | Si1 | Si1 | ||

| сверх | до | max | min | max | max | max | max |

| mm | mm | pm | pm | pm | pm | µm | µm |

| - | 18 | 0 | -8 | 6 | 10 | 5 | 3 |

| 18 | 30 | 0 | -10 | 8 | 10 | 5 | 3 |

| 30 | 50 | 0 | -12 | 9 | 10 | 6 | 3 |

| 50 | 80 | 0 | -15 | 11 | 10 | 7 | 4 |

| 80 | 120 | 0 | -20 | 15 | 15 | 8 | 4 |

| 120 | 180 | 0 | -25 | 19 | 15 | 9 | 5 |

| 180 | 250 | 0 | -30 | 23 | 20 | 10 | 5 |

| 250 | 315 | 0 | -35 | 26 | 25 | 13 | 7 |

| 315 | 400 | 0 | -40 | 30 | 30 | 15 | 7 |

| 400 | 500 | 0 | -45 | 34 | 30 | 18 | 9 |

| 500 | 630 | 0 | -50 | 38 | 35 | 21 | 11 |

| 630 | 800 | 0 | -75 | - | 40 | 25 | 13 |

| 800 | 1000 | 0 | -100 | - | 45 | 30 | 15 |

| 1000 | 1250 | 0 | -125 | - | 50 | 35 | 18 |

| D | Dmp | VDp | Si1 | Si1 | Si1 | ||

| сверх | до | max | min | max | max | max | max |

| mm | mm | pm | pm | pm | pm | pm | pm |

| 18 | 30 | 0 | -13 | 10 | 10 | 5 | 3 |

| 30 | 50 | 0 | -16 | 12 | 10 | 6 | 3 |

| 50 | 80 | 0 | -19 | 14 | 10 | 7 | 4 |

| 80 | 120 | 0 | -22 | 17 | 15 | 8 | 4 |

| 120 | 180 | 0 | -25 | 19 | 15 | 9 | 5 |

| 180 | 250 | 0 | -30 | 23 | 20 | 10 | 5 |

| 250 | 315 | 0 | -35 | 26 | 25 | 13 | 7 |

| 315 | 400 | 0 | -40 | 30 | ↑ | ||

.png)